Sources of solids loading

The largest source of solids loading to the river (90%) occurs through stormwater system discharges, which includes snow melt and rainwater runoff from urban areas. This runoff drains through the stormwater collection system, and the water picks up particles that impact the quality of water downstream.

Historically, the volume of solids delivered to the river by the stormwater system has varied seasonally and annually based mainly on the volume and intensity of rainfall and snow melt – which is reflected in the data reported for 2017 to 2020 (2021 data is currently being finalized and will be reported on in the 2022 sustainability report).

During heavy rain events or accelerated snowmelt, there are two additional sources of solids discharged to the river. At the Gold Bar Wastewater Treatment Plant, high flows are managed by diverting some partially-treated water to the river. This accounts for about 18% of reported solids loading.

Additionally, if the capacity of the combined sewer system to transport wastewater is exceeded, the system is designed to overflow to receiving water bodies in order to prevent sewer backups into buildings. In both cases, the high water flows (which is primarily rain water) also serve to dilute discharges into the river and increase overall river volume, which helps protect waterways.

Investing to protect river water quality

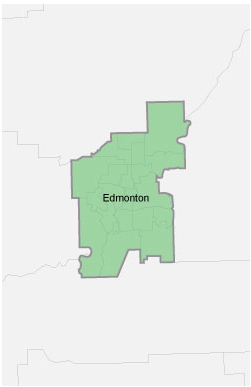

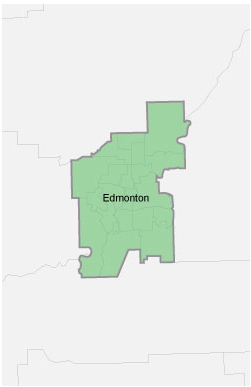

Edmonton's drainage utility transferred to EPCOR's ownership in September 2017, and along with it came accountability for addressing solids loading to the river from the stormwater and sewer systems.

We subsequently developed our Stormwater Integrated Resource Plan (SIRP), which includes more than $900 million in planned investments over 20-years to reduce peak stormwater flows through the use of dry ponds and Low Impact Development, both of which collect and store water during large rainfall events and accelerated snow melt. These investments build on the earlier Combined Sewer Overflow (CSO) control strategy.

These investments will reduce the risk of flooding, increase capacity in the combined sewer system, and filter stormwater before it reaches the river – improving the quality of stormwater entering the river, limiting the occurrence of CSOs, and reducing urban creek erosion.

Through increased monitoring, research, and modelling, we can quantify the sources for the loadings and then manage total loadings from our stormwater and sewage collection system.

A holistic approach to watershed protection