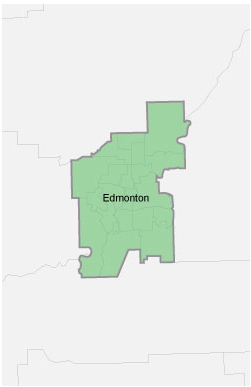

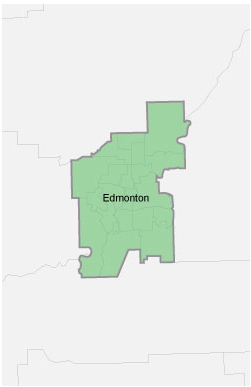

About the High Voltage Testing Facility

Our comprehensive High Voltage Testing Facility (formerly known as the High Voltage Test Lab) in Edmonton is industry compliant and set up to clean, inspect and test just about any piece of safety equipment that you might need. Our test system for high voltage electrical gloves minimizes the potential for a life-threatening mistake. Cover-up equipment, live-line tools and other protective equipment are all Direct Current (DC) tested in accordance with the most stringent standards.

Cost effective testing

Because we operate a DC high voltage test facility, you can expect to pay less and get faster results for your high voltage test services. DC test methods are less damaging to equipment than AC, so less of your equipment is destroyed during testing, allowing for proper repair of the equipment instead of replacement.

Quick and efficient repairs

We know you need your equipment out in the field, not in the shop. Our repair facilities, including a machine shop and paint booth, can accommodate most live line fiberglass insulated tools and equipment repairs quickly and efficiently. Full compliance testing of repaired equipment is done before that equipment is put back into service.

Skilled personnel

Along with our leading-edge test facility, our highly skilled personnel have a depth of experience unmatched in the industry. They have hands-on knowledge of high voltage power lines including high voltage overhead power lines, transmission lines and distribution lines. At EPCOR, we understand the need for reliable, safe equipment better than anyone.

All testing is completed by Journeyman power systems electricians that certify and test to ASTM, IEEE and CSA standards, ensuring quality service and products.

Industry standard compliance

All protective equipment is required by law to be tested at least once a year for compliance with manufacturer specifications and industry standards. Ensuring your high voltage safety equipment meets or exceeds the highest standards reduces the costs of lost-time incidents.

Safety certification

Our certification stamp or label shows that your high voltage electrical equipment meets or exceeds the appropriate standards, ensuring that your workers are using properly tested and compliant equipment. On aerial devices, we inspect the liner, boom, basket, jib and the hydraulic fluid in the lines.